Approximately one third of the world`s population still lacks access to electricity due to the unavailability of fossil fuels locally, the rise in their costs on the international market and the lack of a suitable infrastructure.

The utilisation of small-scale biomass downdraft gasification CHP units which are relatively cheap and portable seems a viable option for addressing this need. However, such systems generally require high quality or specialised grade biomass feedstocks for uninterrupted and trouble free operation, the costs of which are often prohibitive even when available locally. More commonly, locally available biomass feedstocks are of insufficiently high quality resulting in problems such as melting of gasification residues and the development of corrosive deposits in gasifiers.

Upgrading of these low quality biomass feedstock through the use of locally sourced affordable additives could increase the reliability and availability of these systems stability and also create considerable business opportunities for system manufacturers in the global marketplace.

In this research project, municipal and domestic grass clippings (GGC) are being investigated as a widely available low cost potential biomass feedstock, and the melting characteristics of its residue are being studied and examined in the presence of various additives at laboratory scale using a small furnace operated at a temperature typical of the oxidation zone of a downdraft gasifier.

The ash (gasification or combustion residue) of raw grass clippings melts severely, making the material unsuitable for use in gasifier units in its raw form. However, through carefully planned experiments, a strategy has been developed at Thornton Science Park`s laboratories through which ash melting characteristics can be remarkably improved by the addition of calcium- and phosphorous-based additives, some of which are readily available natural waste materials.

This strategy will now be tested under real conditions using one of the commercial biomass CHP units manufactured by Biogen Systems Ltd., a collaborative partner with University of Chester on this research project.

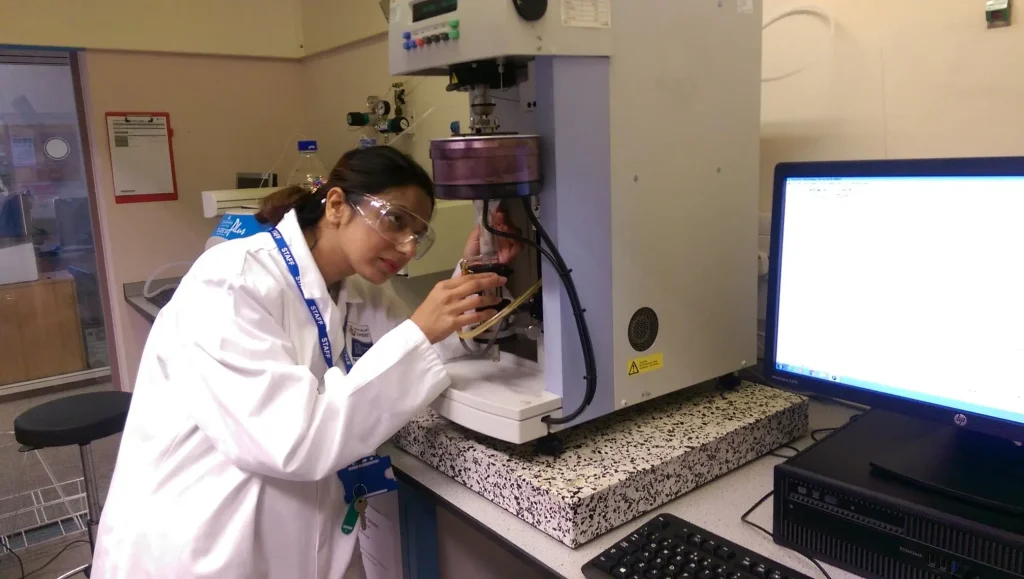

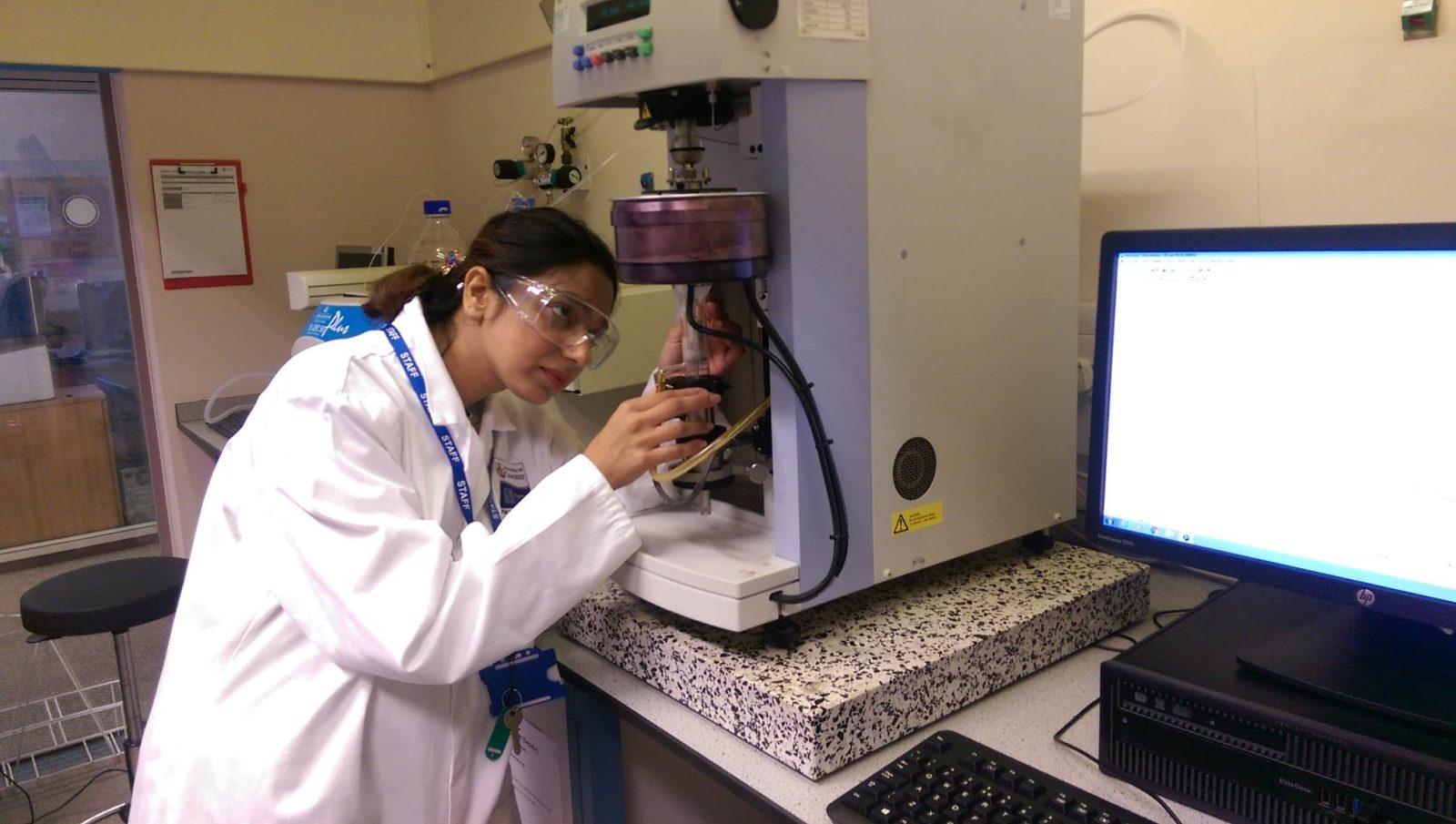

Mubashra Latif is studying for her PhD at the University of Chester within the Faculty of Science and Engineering, where she is investigating alternative feedstocks to turn into energy.

We’re delighted to welcome her to our Didsbury Scibar event to present on this topic.

Monday 16th March @ 18:30. FREE admission

The Albert Club, Old Lansdowne Road, West Didsbury, Manchester M20 2PA